Boosters for Piston Compressors

| Model | Cylinders/Phase | RPM | Bar ↑ | Bar ↓ | L/min In | L/min Out | kW | Weight (kg) | Dimensions |

| BA10 | 2/1 | 695 | 6 | 40 | 1200 | 875 | 7.5 | 220 | 1210×640×715 |

| BA10 | 2/1 | 695 | 8 | 40 | 1485 | 1190 | 7.5 | 220 | 1210×640×715 |

| BA10 | 2/1 | 695 | 10 | 40 | 1870 | 1575 | 7.5 | 220 | 1210×640×715 |

| - | - | - | - | - | - | - | - | - | - |

| BA15 | 2/1 | 1130 | 6 | 40 | 1990 | 1510 | 11.0 | 240 | 1210×660×715 |

| BA15 | 2/1 | 1130 | 8 | 40 | 2450 | 2045 | 11.0 | 240 | 1210×660×715 |

| BA15 | 2/1 | 1130 | 10 | 40 | 3060 | 2680 | 11.0 | 240 | 1210×660×715 |

| - | - | - | - | - | - | - | - | - | - |

| BA20 | 3/1 | 1130 | 6 | 40 | 3040 | 2280 | 15.0 | 310 | 1210×680×715 |

| BA20 | 3/1 | 1130 | 8 | 40 | 3715 | 3070 | 15.0 | 310 | 1210×680×715 |

| BA20 | 3/1 | 1130 | 10 | 40 | 4590 | 3980 | 15.0 | 310 | 1210×680×715 |

| - | - | - | - | - | - | - | - | - | - |

| BA25 | 3/1 | 1270 | 6 | 40 | 3425 | 2620 | 18.5 | 330 | 1210×680×715 |

| BA25 | 3/1 | 1270 | 8 | 40 | 4200 | 3535 | 18.5 | 330 | 1210×680×715 |

| BA25 | 3/1 | 1270 | 10 | 40 | 5160 | 4560 | 18.5 | 330 | 1210×680×715 |

Remeza piston booster compression units are designed to increase the pressure of air already compressed by a first-stage compressor. They are used wherever high flow rates (up to 4500 liters per minute) are required at relatively high pressures (up to 40 bar).

Design Features

Piston blocks from the world leader BOGE (Germany).

Unique solutions such as minimal clearances between cylinders ensure high efficiency of the piston units. Nevertheless, the greatest gains in efficiency are obtained from boosting pressure in the existing network, since the energy consumption of a screw compressor/booster combination is significantly lower compared to two-stage or three-stage compressors.

Connecting Rods to Power Reservoir Cranks with large control socket. The connecting rod is equipped with an eternal wear-resistant wire on the crankshaft axis side.

Special Crankshaft Crankshaft made from a single piece, dynamically balanced, with a very wide control socket, with roller bearings on both sides.

Reinforced Valves Perax-type valves that combine suction/discharge valve with extended service life. Stretched cross-sectional diameters are installed that help reduce the average resistance to air flow.

Additional Oil Reservoir The compressor is equipped with an additional oil reservoir that extends the service interval. Synthetic oil with a change interval of 2000 operating hours is used.

Air Flow Hood The cooling air flow is directed to the cylinders of the block, providing efficient cooling and enabling continuous operation.

The compressors are not limited in the duty cycle due to their design: piston speed of about three meters per second (for comparison, diesel engines operate at speeds of 7-15 meters per second), reduces the heat generation of components and consequently reduces loads and wear, ensuring low operating costs, cost savings and long service life.

Maximum Flexibility in Setting Primary and Final Pressures

Boosters can be easily integrated with screw compressors with final pressures from 6 to 10 bar (high pressure). The final pressure can be changed at any time as needed to suit the user's production requirements.

Control System

Airmaster P1 controller in BA series compressor units: - Operating time counter. - Shows output pressure. Ability to programmatically set pressure limits within the allowed range. - Monitors motor load. Automatic shutdown of the compressor unit in case of accidents with display of warning messages.

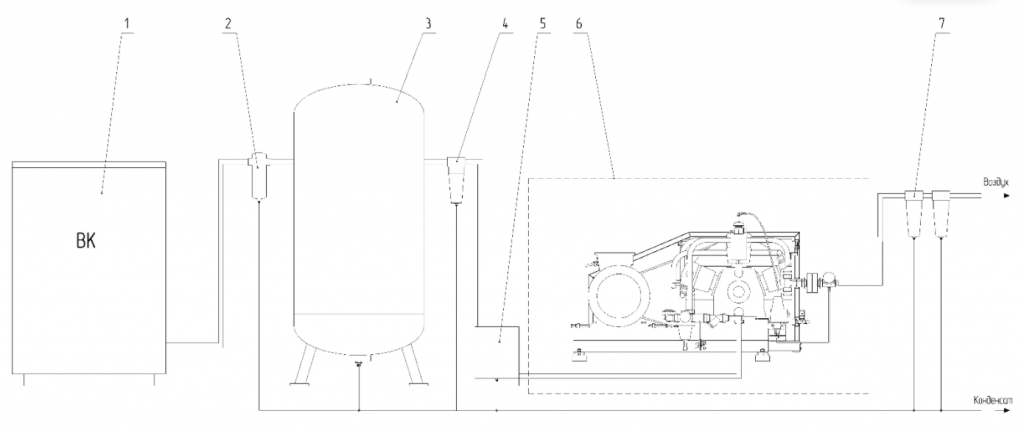

Compressor Station Scheme

1. First stage air compressor (screw air compressor) 2. Oil-water separator 3. Air receiver 4. Pre-filter with 3 micron size 5. Refrigerated air dryer 6. Booster 7. Filters with additional filtration of 0.01 micron size

Applications

- Food industry - Automotive industry - PET bottle blowing

Compressors